| MAGNABEND HANDYMAN MODEL |

BENDING

BEAM & EXTENSION

Bending Beam & Extension drawing: Enlarged view, PDF drawing.

Microswitch Actuator drawing:

"Handyman" Index page.

Contact Alan Magnabend Homepage Alan's Homepage

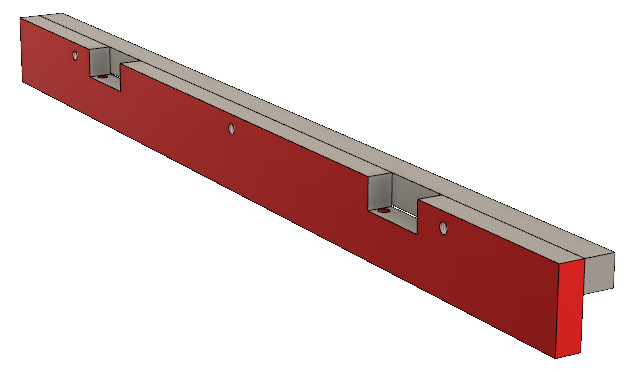

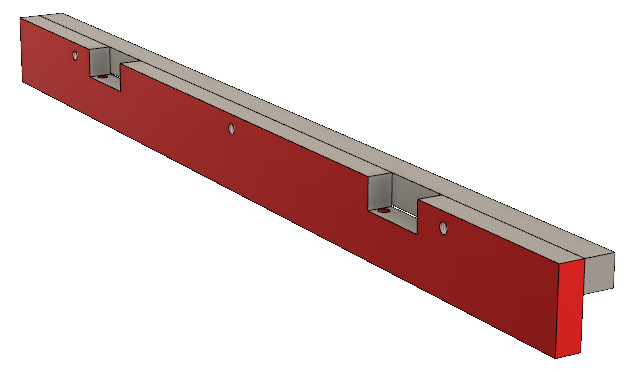

The Bending Beam for the Handyman model has been compacted compared

with previous Magnabend machines of this length.

Because of the placement of the hemi hinges a depth of only 50mm is perfectly adequate to give the beam the required stiffness. This saves weight and cost.

The Handyman design promised a minimal requirement for milling. However some milling is needed for the Bending Beam and for the Front Pole of the machine to provide rebates for the hinges. The hinge rebates are the same for both the Bending Beam and for the Front Pole and thus these two components can be gang milled in a single operation using, say, a 50mm face mill.

If a milling machine is not available then it is possible to achieve this operation with just a mill-drill, using very light cuts.

Material for the Bending Beam is either 50 x 16 mm BMS, or the equivalent imperial size of 2" x 5/8" is close enough. Hot rolled 50 x 16mm is also a possibility.

The Beam Extension specifies 19.05 mm (3/4") BMS square bar, although the exact size of the extension is not very critical and thus you could use 16mm square or 20mm square. (However those alternate sizes are not suitable for the Pole Spacers (within the magnet body) which do require 3/4" square).

Because of the placement of the hemi hinges a depth of only 50mm is perfectly adequate to give the beam the required stiffness. This saves weight and cost.

The Handyman design promised a minimal requirement for milling. However some milling is needed for the Bending Beam and for the Front Pole of the machine to provide rebates for the hinges. The hinge rebates are the same for both the Bending Beam and for the Front Pole and thus these two components can be gang milled in a single operation using, say, a 50mm face mill.

If a milling machine is not available then it is possible to achieve this operation with just a mill-drill, using very light cuts.

Material for the Bending Beam is either 50 x 16 mm BMS, or the equivalent imperial size of 2" x 5/8" is close enough. Hot rolled 50 x 16mm is also a possibility.

The Beam Extension specifies 19.05 mm (3/4") BMS square bar, although the exact size of the extension is not very critical and thus you could use 16mm square or 20mm square. (However those alternate sizes are not suitable for the Pole Spacers (within the magnet body) which do require 3/4" square).

Bending Beam & Extension drawing: Enlarged view, PDF drawing.

Microswitch Actuator drawing:

"Handyman" Index page.

Contact Alan Magnabend Homepage Alan's Homepage

This

page last updated: 6 June 2021